GE FANUC/ALSTOM AL122A - Martek Power CD101320 C145

The GE FANUC/ALSTOM AL122A is a robust and versatile automation solution engineered specifically for demanding environments within the power industry, petrochemical sector, and general automation applications. Recognized for its exceptional input/output capacity, durability, and reliable performance, the AL122A stands out as a critical component in industrial automation systems requiring precision control and long-term operational stability.

At its core, the GE FANUC/ALSTOM AL122A boasts an advanced I/O architecture, supporting a high-density arrangement of digital and analog inputs and outputs. This capacity enables seamless integration with a wide array of sensors, actuators, and control devices, ensuring rapid data processing and real-time control feedback. The AL122A is built to withstand harsh industrial conditions, featuring ruggedized construction with resistance to temperature extremes, vibration, and electrical interference. This durability ensures minimal downtime and reduces maintenance costs, making it ideally suited for continuous operation in power plants, petrochemical refineries, and automated manufacturing lines.

Performance metrics for the AL122A reveal a system optimized for low latency communication and precise automation control. Its processing unit operates with high throughput capabilities, facilitating complex control algorithms and enabling sophisticated process management. The AL122A supports various communication protocols, enhancing interoperability with existing GE FANUC/ALSTOM automation products such as the IC693BEM340 and the MVC3002-4001 modules. This interoperability is crucial for expanding control systems or upgrading legacy equipment without extensive overhauls.

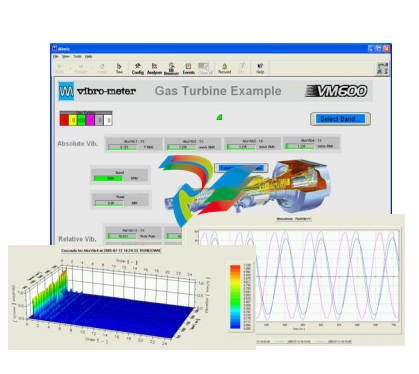

In practical applications, the GE FANUC/ALSTOM AL122A excels in scenarios demanding reliability and precision. For example, in the power industry, the AL122A effectively manages turbine control systems, ensuring optimal power generation efficiency and safety. In petrochemical plants, it handles complex chemical process controls where precise timing and accuracy are vital to maintaining product quality and safety standards. Additionally, within general automation frameworks, it enables manufacturers to implement flexible production lines with real-time monitoring and adaptive process adjustments.

Compared to other models within the GE FANUC/ALSTOM portfolio, the AL122A offers a unique balance of high I/O density and ruggedness. While models like the GE FANUC/ALSTOM DINVERTER and the GE FANUC/ALSTOM BLUELINE focus more on motor control and basic automation tasks, the AL122A is designed for more complex control environments requiring extensive input/output interfacing and robust operational stability. Similarly, while the GE FANUC/ALSTOM SCN804 series and the MVS3000-4001 provide specialized functions in network communications and supervisory control, the AL122A is distinguished by its comprehensive integration capabilities and adaptability to diverse industrial applications.

Alongside the GE FANUC/ALSTOM AL122A, complementary products such as the GE FANUC/ALSTOM JOYSTICK CONTROLLER STATION and the GE FANUC/ALSTOM EP3-E-4-EN enhance manual control and operator interface functions, broadening the automation system’s flexibility. For power-specific components, the GE FANUC/ALSTOM Power Preheater and Power Grinding Roll Lock Nut ensure mechanical reliability and efficiency, synergizing well with the AL122A’s control capabilities. Additional modules like the GE FANUC/ALSTOM PIB102A-3BEB0180-A and the GE FANUC/ALSTOM Microverter D 3.4/500 provide essential control and power conversion functions that integrate seamlessly in larger GE FANUC/ALSTOM automation setups.

The application of the AL122A in power industry, petrochemical, and general automation environments is further supported by its compatibility with GE FANUC/ALSTOM’s extensive range of components such as the SCN804D and the GECOSTAT MC15-M2, which are often deployed for advanced process monitoring and control. This extensive ecosystem of automation products ensures that the AL122A can be tailored to meet specific operational demands, providing a scalable and future-proof solution.

In summary, the GE FANUC/ALSTOM AL122A is a high-performance automation controller that delivers exceptional I/O capacity, durability, and processing power. Its proven track record in power generation, petrochemical processing, and general industrial automation underscores its reliability and versatility. When considered alongside other GE FANUC/ALSTOM automation products like the DINVERTER, IC693BEM340, and SCN804, the AL122A emerges as a cornerstone technology, enabling complex control systems that meet the rigorous demands of today’s industrial environments. For organizations seeking dependable and scalable automation solutions, the AL122A provides unmatched value and operational excellence.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.png)