GE Fanuc IC200ALG430 Versamax PLC - Industrial Control Excellence

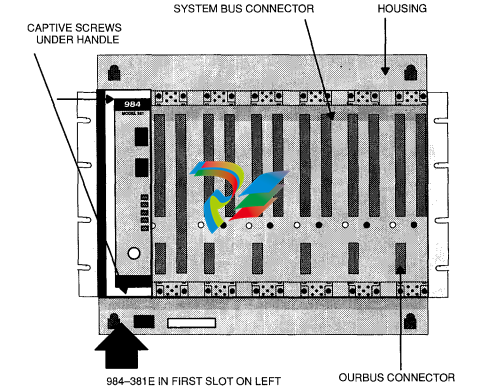

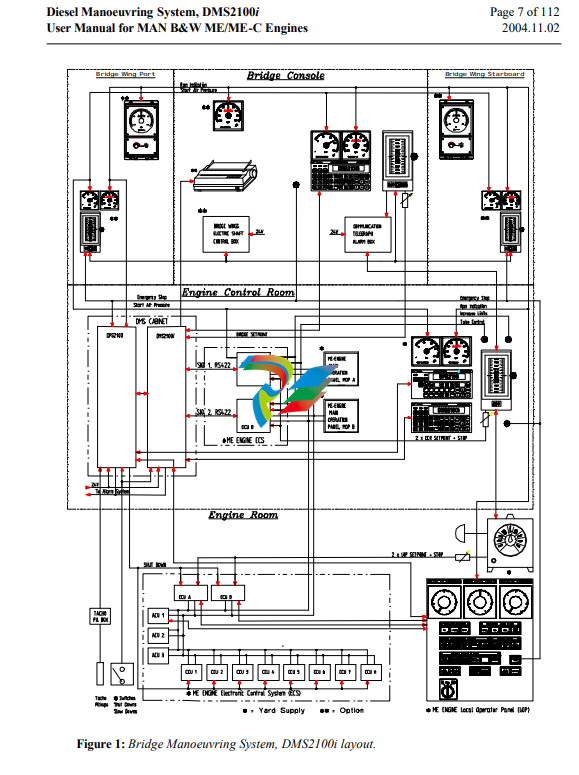

The GE Fanuc IC200ALG430 Versamax PLC stands out as a robust and versatile automation controller designed to meet the demanding needs of industries such as power generation, petrochemical processing, and broad-spectrum automation. Engineered for high performance, durability, and scalability, this PLC offers a comprehensive solution for complex control tasks, making it an ideal choice for both critical infrastructure and industrial manufacturing environments.

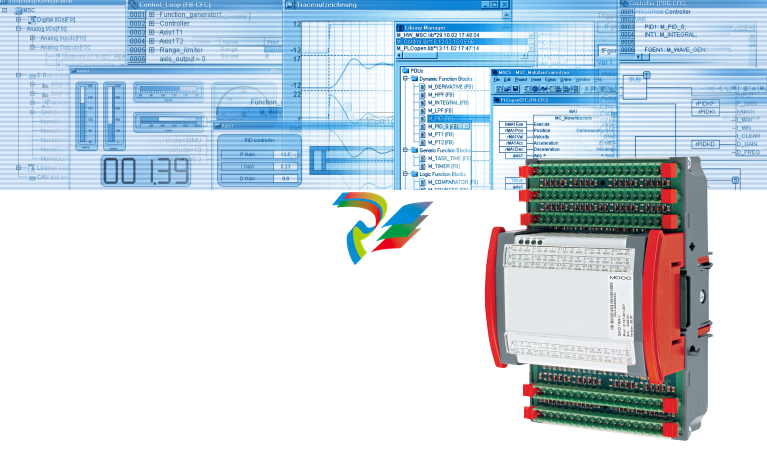

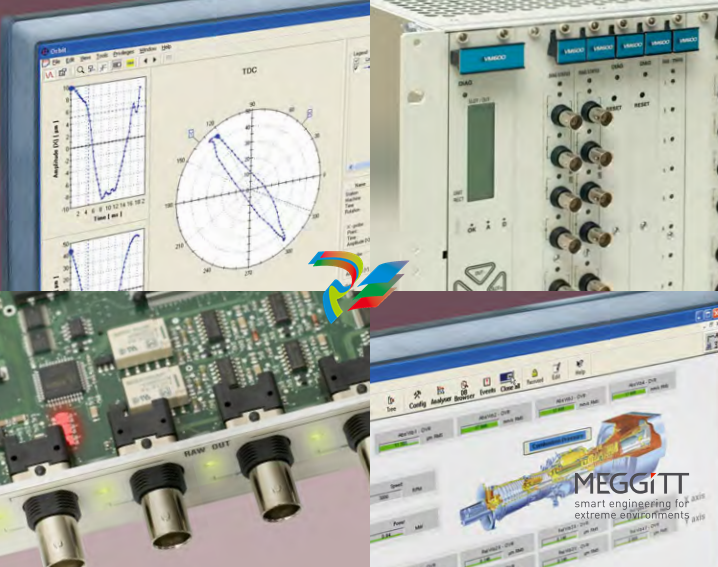

One of the key technical features of the GE Fanuc IC200ALG430 Versamax PLC is its impressive input/output capacity. It supports a wide array of I/O modules, enabling users to customize their control systems with extensive digital and analog inputs and outputs. This flexibility ensures seamless integration into various operational setups, whether managing power distribution, monitoring chemical processes, or controlling manufacturing lines. The system's high-speed processing capabilities facilitate real-time data acquisition and control, ensuring precision and responsiveness in mission-critical applications.

Durability is at the core of the GE Fanuc IC200ALG430's design. Built to withstand harsh industrial conditions, it offers excellent resistance to temperature fluctuations, vibration, and electrical noise. Its rugged construction guarantees long-term reliability, minimizing downtime and maintenance costs. Additionally, the PLC supports extensive diagnostic and troubleshooting features, which help operators quickly identify faults and maintain optimal performance.

Performance metrics of the GE Fanuc IC200ALG430 Versamax PLC include fast scan times and deterministic operation, essential for applications requiring precise timing and synchronization. Its modular architecture allows for easy expansion, accommodating growing control demands without the need for complete system overhaul. Whether deploying in a distributed control system or a centralized setup, this PLC maintains consistent, high-quality operation.

In real-world scenarios, the GE Fanuc IC200ALG430 excels in power industry applications such as grid management and power plant automation, where reliable control of multiple input signals and output commands is critical. In petrochemical environments, its robust design ensures safe operation amid hazardous conditions, supporting complex process automation with high accuracy. General automation tasks, including assembly lines, packaging, and material handling, benefit from its scalability and seamless integration with other GE automation products.

Compared to other models within the GE portfolio, such as the GE IS220PPRFH1A, GE IS200VCRCH1BBC, or GE IC693MDL753H, the GE Fanuc IC200ALG430 offers a balanced combination of high I/O capacity, durability, and performance scalability. While models like the GE A20B-2003-0311 or GE IS200VCRCH1BBC focus on specific functions, the Versamax PLC provides a broad, comprehensive control platform suitable for diverse industrial applications. Its compatibility with related models such as the GE IS200BICMH1AAA or GE DS215DMCBG1AZZ03A allows for tailored system configurations that optimize operational efficiency.

Alongside the GE Fanuc IC200ALG430 Versamax PLC, we also offer other reliable GE automation products like the GE 269PLUS-D/O-261-100P-120 for power management, the GE IC693MDL654 for complex process control, and the GE UR6AV or UR6CH series for communication and remote monitoring. These models collectively enhance automation solutions, ensuring comprehensive coverage of control, communication, and diagnostic needs.

In conclusion, the application of Fanuc IC200ALG430 Versamax PLC in power industry, petrochemical, and general automation exemplifies its adaptability, robustness, and high-performance capabilities. Whether upgrading existing systems or designing new automation architectures, this PLC is a strategic investment that delivers long-term reliability and operational excellence. Its integration with other GE automation products ensures a cohesive, flexible control environment tailored to the evolving demands of modern industry.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.png)