GE IC693CPU331RR - High-Performance Series 90-30 Controllers for Industrial Automation

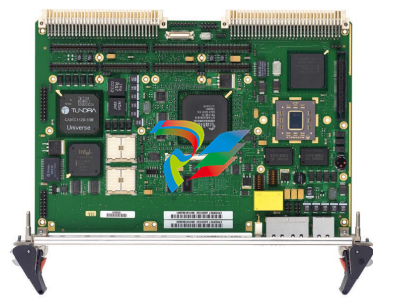

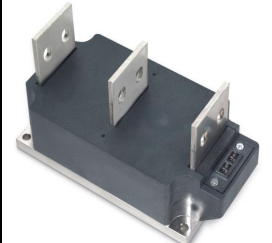

The GE IC693CPU331RR is a robust and versatile automation controller designed to meet the demanding needs of the power industry, petrochemical sector, and a wide range of general automation applications. Built on GE's proven expertise in industrial automation, this model offers a compelling combination of high-performance processing, extensive I/O capacity, and enhanced durability, making it an ideal choice for complex control systems requiring reliable operation in challenging environments.

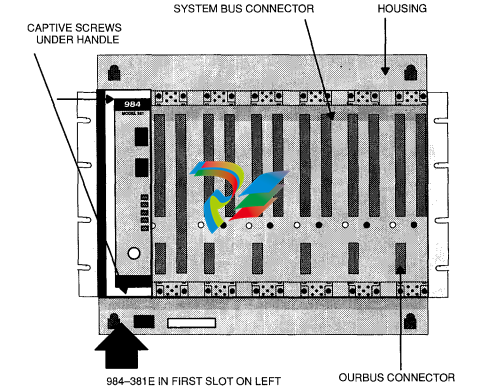

At its core, the GE IC693CPU331RR features a powerful processor capable of executing multiple control tasks simultaneously, ensuring rapid response times and seamless operation. Its architecture supports a significant number of I/O points, enabling comprehensive integration with various sensors, actuators, and field devices. This extensive I/O capacity enhances system flexibility and simplifies expansion, reducing the need for additional controllers and interfaces. The controller's design emphasizes durability, with rugged construction suitable for harsh industrial environments, including exposure to vibration, temperature fluctuations, and electrical noise.

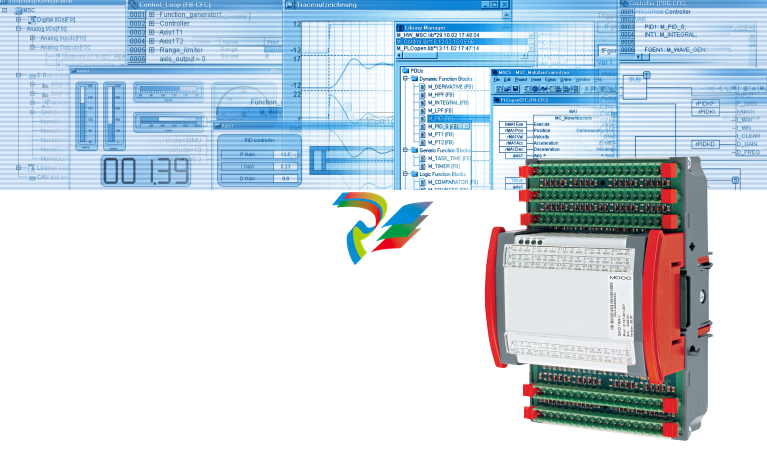

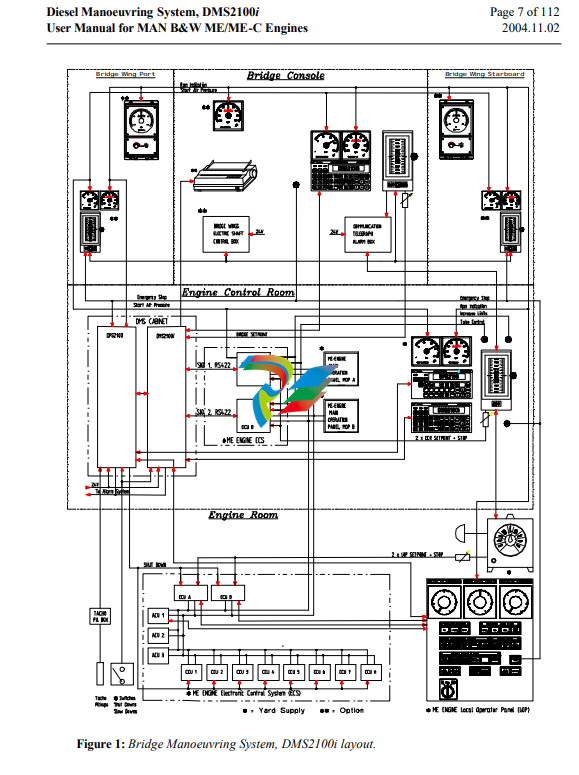

Performance metrics of the GE IC693CPU331RR demonstrate its capability to handle demanding automation tasks efficiently. It boasts high-speed processing with reliable data throughput, ensuring minimal latency in critical control operations. Its real-time responsiveness is essential in applications such as power plant control systems, petrochemical process automation, and large-scale manufacturing setups, where timing precision directly impacts safety and productivity. Moreover, the controller supports various communication protocols, facilitating seamless integration with other automation components and SCADA systems.

In real-world scenarios, the GE IC693CPU331RR excels in controlling complex processes within power generation facilities, managing turbine and generator operations with precision. In the petrochemical industry, it effectively monitors and controls refining processes, ensuring safety and efficiency. Its robustness makes it suitable for factory automation environments, where continuous, reliable operation is paramount. For general automation, it provides a scalable, dependable solution for manufacturing lines, material handling, and other industrial control tasks.

Compared to other models within GE's extensive product lineup, the IC693CPU331RR stands out due to its balanced emphasis on processing power, I/O capacity, and environmental durability. For instance, while models like the GE IC200MDL750J or GE IC693DSM302-RE focus on specific control functions or communication capabilities, the IC693CPU331RR offers a comprehensive platform capable of supporting complex, multi-faceted automation projects. Its compatibility with a range of related models such as the GE IS220PRTDH1A for high-speed data acquisition, GE DS3800HDDA for distributed I/O, or GE IC3600LSFD1B for process control adds to its versatility. Additionally, models like the GE IS200TREGH1BEC and GE IC200MDL643 complement the IC693CPU331RR by providing specialized control modules, expanding system capabilities.

The integration of the GE IC693CPU331RR alongside other GE automation products like GE IS200EPSMG1AED, GE IC695PSA140E, or GE DS200TCPDG1ADC ensures a comprehensive automation ecosystem tailored to industry-specific needs. This synergy allows engineers to design scalable, resilient control systems that optimize operational efficiency and safety.

In summary, the GE IC693CPU331RR is a cornerstone of GE's automation product portfolio, delivering high-performance control with exceptional durability for the power, petrochemical, and general automation sectors. Its advanced features, extensive I/O support, and compatibility with a broad range of related models make it a top choice for industrial automation professionals seeking reliability and scalability. Leveraging application of IC693CPU331RR in power industry, petrochemical, and general automation ensures optimized process control, enhanced safety, and improved operational efficiency across diverse industrial environments.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.png)