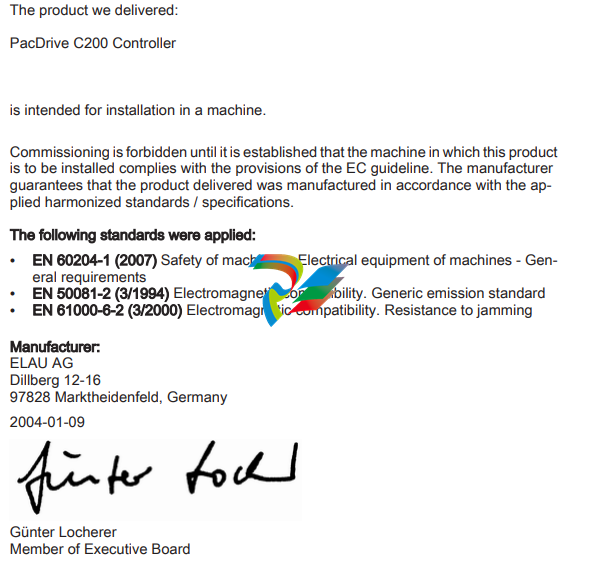

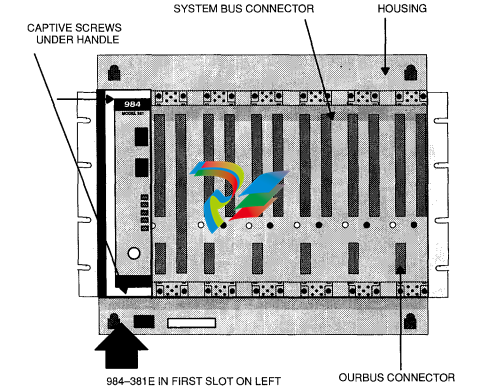

GE IC697BEM711 - Industrial PLC Expansion Module for Enhanced System Connectivity

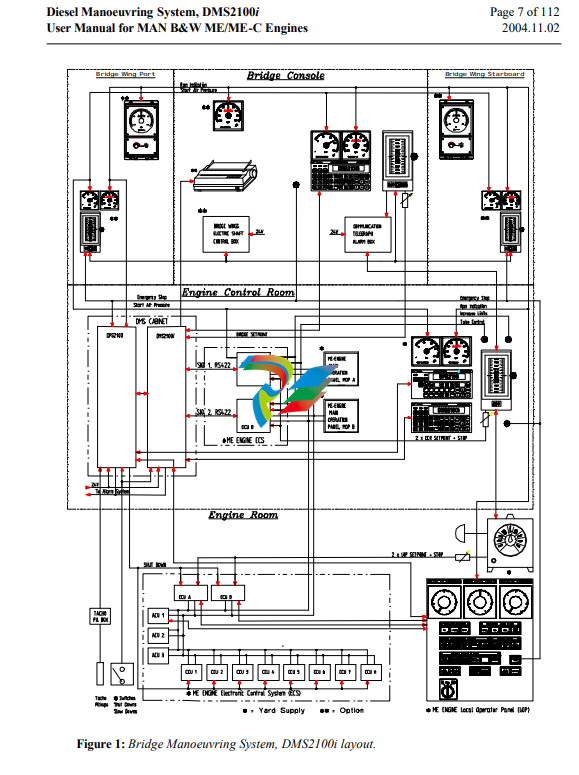

The GE IC697BEM711 is a highly advanced and reliable I/O terminal module designed to meet the demanding needs of modern industrial automation systems. Engineered by GE, a global leader in automation products, the IC697BEM711 offers exceptional input/output capacity, durability, and performance, making it an ideal choice for applications within the power industry, petrochemical sector, and broad automation environments. Its robust design ensures long-term operation in harsh industrial settings, providing consistent and accurate data acquisition and control.

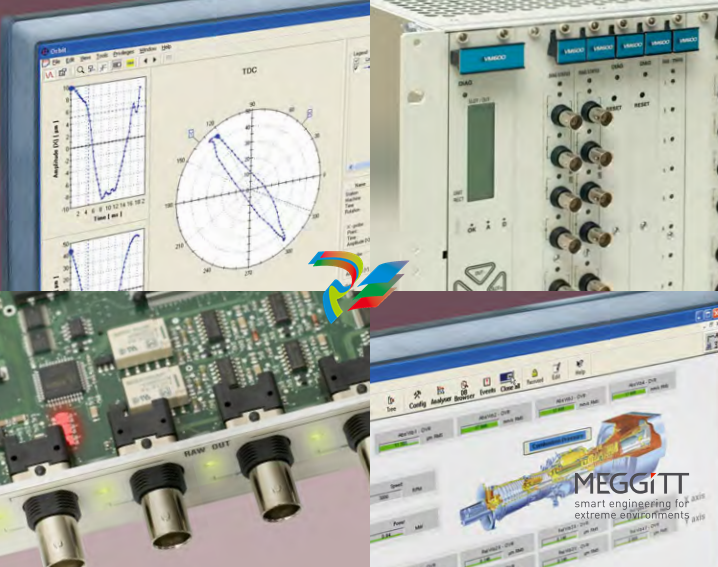

The key technical features of the GE IC697BEM711 include its high-density I/O capabilities, supporting a substantial number of input and output points—making it suitable for complex automation tasks. This module supports both digital and analog I/O functions, enabling versatile interfacing with sensors, actuators, and control devices. Its rugged construction is designed for high durability, withstanding extreme temperatures, vibrations, and electrical noise prevalent in industrial environments. The IC697BEM711 also boasts fast processing speeds and low latency, ensuring real-time responsiveness essential for critical control processes.

In real-world scenarios, the GE IC697BEM711 excels in power plant automation where reliable data collection from numerous sensors is crucial for maintaining grid stability. Its application in petrochemical facilities supports complex process control with precise monitoring of temperature, pressure, and flow rates, contributing to safety and operational efficiency. Additionally, in general automation, the module plays a pivotal role in manufacturing lines, where seamless communication between various control units ensures smooth and synchronized production processes.

Compared to other models within GE’s extensive product portfolio, the IC697BEM711 stands out for its high input/output density and robustness. For example, while models like GE IC693PWR332 and GE IC200ALG320J focus on power supply management and analog processing respectively, the IC697BEM711 offers a comprehensive solution with extensive digital and analog I/O capabilities in a single module. Its design provides an optimal balance of performance and durability, making it suitable for both new installations and upgrade projects.

Alongside the GE IC697BEM711, we also offer several complementary GE automation products to enhance system integration and performance. For instance, the GE IS200ERIOH1AAA and GE IC693ACC310 modules are ideal for communication and control interface enhancements, while the GE DS200SHVIG1B and GE DS200TBQBG1ACB provide advanced signal conditioning and data processing functions. For power management, models like GE IC693PWR332 and GE IC697MDL750 offer robust power supply solutions to ensure uninterrupted operation. The GE 8607ERL and GE IC670CHS101C modules further extend the capabilities into high-speed processing and safety functions, respectively.

In summary, the GE IC697BEM711 is a cornerstone of GE’s automation products, delivering reliable high-density I/O solutions tailored for challenging industrial environments. Its application in the power industry, petrochemical, and general automation underscores its versatility and performance edge. When selecting automation modules, the IC697BEM711 provides a robust, efficient, and scalable platform that integrates seamlessly with other GE models such as the GE 750-P5-G5-S5-HI-A20-R-E, GE IC3600SIXK1A1A, and GE IC695CRU320-BB, ensuring comprehensive control solutions across diverse industrial sectors. Choosing GE’s automation products, including the IC697BEM711, guarantees operational stability, enhanced productivity, and future-proof system architecture for your industrial automation needs.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.png)