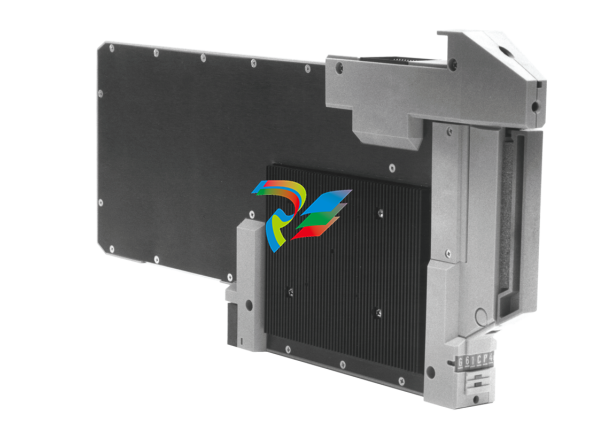

GE IS220PDIOH1A - Advanced PLC Module for Industrial Automation

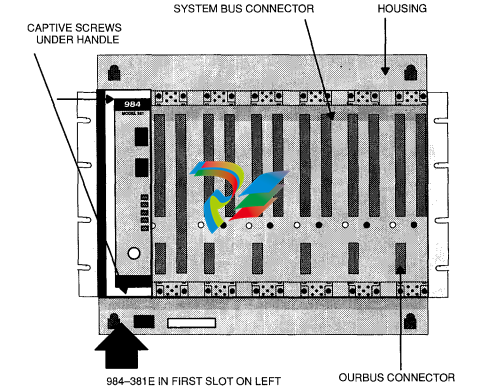

The GE IS220PDIOH1A stands out as a robust and versatile I/O module designed specifically for demanding automation environments across various industries, including power generation, petrochemical processing, and general industrial automation. Engineered with advanced features, this module offers high input/output capacity, exceptional durability, and reliable performance — making it an ideal choice for controlling and monitoring complex systems.

At its core, the GE IS220PDIOH1A provides a substantial number of input and output channels, enabling seamless integration with a broad range of sensors, actuators, and control devices. Its high-density design allows for efficient space utilization in control panels, while maintaining the capability to handle diverse signal types, including digital and analog signals. This versatility ensures the module can accommodate varying operational requirements, whether for monitoring voltage levels in power plants or managing chemical flow rates in petrochemical facilities.

Durability is a hallmark of the IS220PDIOH1A. Built to withstand harsh industrial environments, it features ruggedized construction, resistance to electrical noise, and a wide operating temperature range. Its reliable performance under extreme conditions ensures minimal downtime and reduces maintenance costs — critical factors for industries where system reliability is paramount. Additionally, the module's robust design supports long-term operation, aligning with the high standards of GE’s automation products.

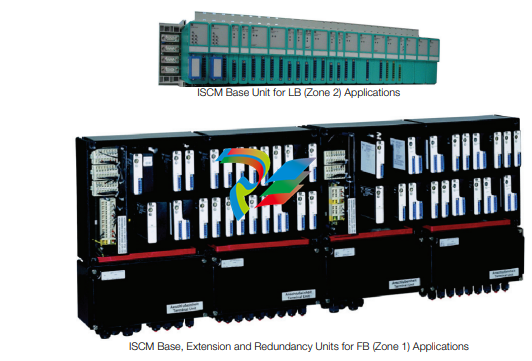

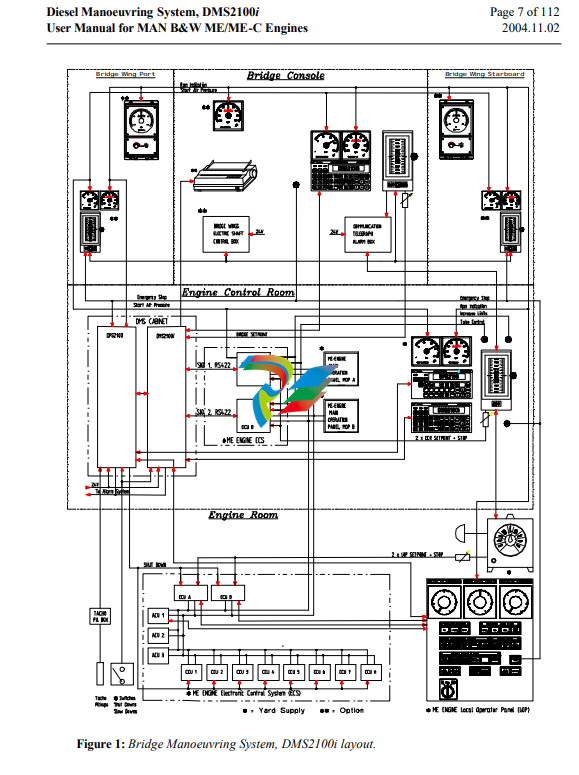

The application of IS220PDIOH1A is particularly prominent in power industry settings, where precise control and real-time data acquisition are essential for grid stability and efficient energy management. In petrochemical plants, it facilitates the safe and efficient operation of processing units, providing critical input/output functions for monitoring chemical reactions and controlling safety systems. Moreover, in general automation scenarios, the module integrates seamlessly with GE’s broader automation solutions, such as the IC693MAR590 or IC693CPU341, to deliver comprehensive control strategies.

Compared to other models within the GE family, such as the GE UR6AV, GE IC200MDD844, or GE DS215TCDAG1BZZ01A/DS200TCDAG1BDB, the IS220PDIOH1A offers a unique combination of high I/O capacity and ruggedness tailored for high-demand applications. For instance, while the GE IC693PWR321AA provides power management capabilities, and the GE IC697MDL350 offers advanced data processing, the IS220PDIOH1A specializes in I/O interfacing, making it the backbone of control systems that require extensive signal handling.

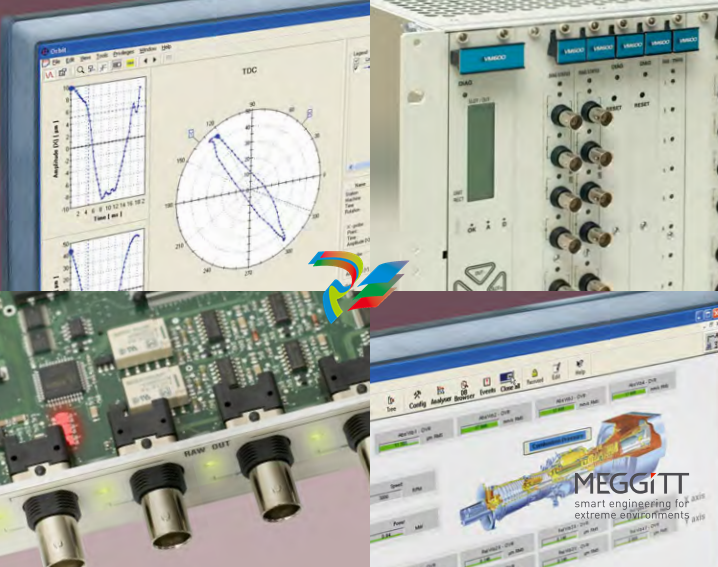

Alongside the GE IS220PDIOH1A, industry professionals often incorporate other GE automation products such as the GE UR9HH for high-speed data acquisition, or the GE IC693CPU331 for centralized control processing. For safety-critical applications, models like GE 531X133PRUALG1 and GE 323A4747 are used to enhance system reliability. The GE DS200CPCAG1R and GE IC660EBD025 further complement control architectures by providing communication and I/O expansion functionalities, ensuring a comprehensive automation solution.

In sum, the GE IS220PDIOH1A stands as a cornerstone product within GE’s broad portfolio of automation solutions. Its high input/output capacity, rugged construction, and proven performance make it a reliable choice for industries where precision, durability, and efficiency are non-negotiable. Whether employed in power plants, petrochemical complexes, or large-scale manufacturing facilities, the application of IS220PDIOH1A continues to demonstrate how GE automation products deliver critical control and monitoring capabilities essential for modern industrial operations. Its integration with other models like the GE IC693MDL241 or GE IC697MDL653 further enhances system robustness, ensuring long-term operational excellence across diverse industrial landscapes.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.png)