GE DS200CTBAG1ADD - Terminal Board for Reliable Industrial Automation

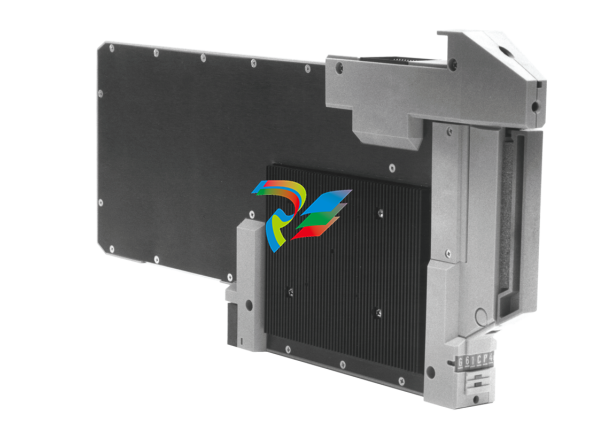

The GE DS200CTBAG1ADD stands out as a robust and high-performance controller designed to meet the demanding needs of the power industry, petrochemical plants, and general automation applications. Engineered with precision and durability in mind, this model offers exceptional input/output capacity, ensuring seamless integration and reliable operation in complex industrial environments. Its advanced architecture supports a wide range of I/O modules, enabling it to handle extensive data acquisition, control, and communication tasks efficiently.

One of the key technical features of the GE DS200CTBAG1ADD is its impressive input/output capacity, making it ideal for applications requiring high-speed processing and extensive signal handling. It boasts a high number of digital and analog I/O points, facilitating comprehensive control over industrial processes. Its rugged construction guarantees durability, withstanding harsh operating conditions such as temperature fluctuations, vibrations, and electrical noise common in power plants and petrochemical facilities. Performance metrics include fast response times, high reliability, and fault tolerance, ensuring continuous operation with minimal downtime, which is critical in mission-critical industrial environments.

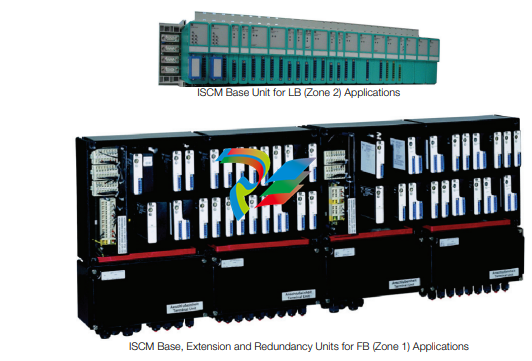

In real-world scenarios, the GE DS200CTBAG1ADD excels in controlling complex automation sequences, managing power distribution systems, and overseeing safety-critical operations. For instance, in power generation facilities, it can regulate turbines, monitor grid stability, and coordinate switchgear operations seamlessly. In petrochemical plants, it ensures precise process control, from refining to chemical synthesis, maintaining safety and efficiency. Its robust design and extensive I/O capabilities also make it suitable for general automation tasks such as conveyor control, HVAC management, and industrial machinery automation, where reliability and real-time responsiveness are paramount.

Compared to other GE automation products, the DS200CTBAG1ADD offers a unique combination of high I/O capacity, rugged durability, and flexible configuration options. For example, models like the GE IS215UCVEH2A and GE IC697RCM711 focus on specific control functions, but the DS200CTBAG1ADD provides a more comprehensive solution suitable for large-scale automation systems requiring extensive data handling. Its compatibility with a broad range of I/O modules, such as the GE DS3800HSAA1T1M or the GE DS3800HSQD, enhances its versatility, allowing it to adapt to diverse industrial needs. Additionally, its performance metrics surpass many counterparts, providing faster processing speeds and enhanced fault tolerance, which are essential for maintaining operational integrity in critical applications.

Alongside the GE DS200CTBAG1ADD, industry professionals often utilize complementary models like the GE IC693MDL753 for motor control, the GE IC200UEX211-C for safety and protection functions, and the GE G60E00HAHF8LHXXM8LPXXUXXWXX for advanced communication interfaces. These models, together with the DS200CTBAG1ADD, form a comprehensive automation ecosystem capable of addressing complex industrial challenges. Other compatible controllers such as the GE IC687BEM713 and GE IC3600LSFD1B further extend system capabilities, ensuring seamless integration across various subsystems. The availability of these models within the GE automation product lineup underscores the company's commitment to providing reliable, scalable, and versatile control solutions.

Incorporating the GE DS200CTBAG1ADD into your automation setup ensures high reliability, extensive I/O handling, and robust performance tailored for demanding applications in the power industry, petrochemical sector, and general industrial automation. Its compatibility with a wide range of GE models like the GE IS200VPROH2B and GE IC200CPU005, along with its proven track record in industrial environments, makes it a preferred choice for engineers seeking durable and efficient control solutions. Whether managing power distribution, refining processes, or automating manufacturing lines, the application of DS200CTBAG1ADD guarantees enhanced operational efficiency and safety, reaffirming GE’s position as a leader in industrial automation products.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.png)