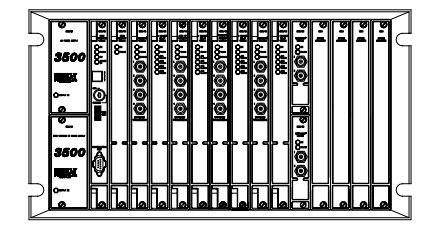

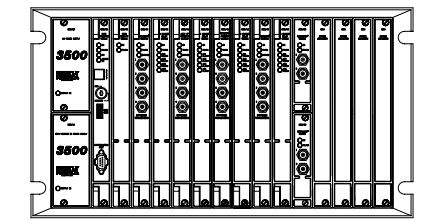

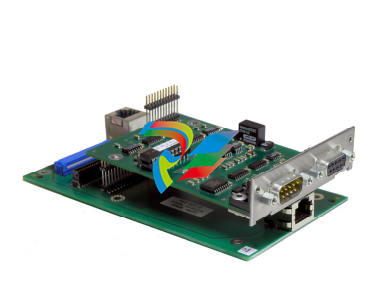

Honeywell 8C-PCNT02 - 514543363-275 module

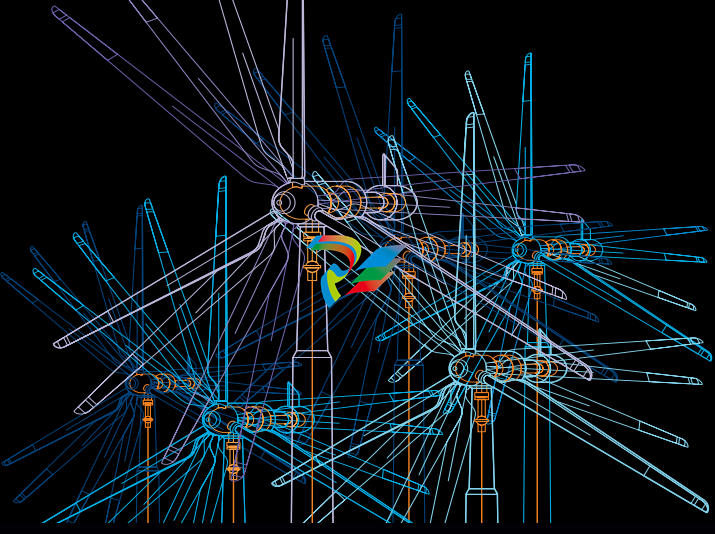

The Honeywell 8C-PCNT02 stands out as a robust and versatile automation product designed specifically to meet the demanding requirements of the power industry, petrochemical sector, and general automation applications. Engineered with precision and reliability in mind, this model delivers exceptional input/output capacity, durability, and performance metrics that set it apart in its class.

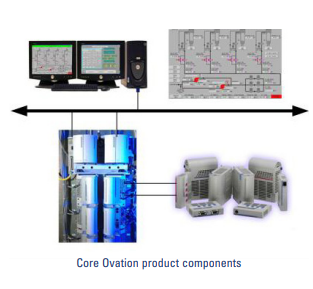

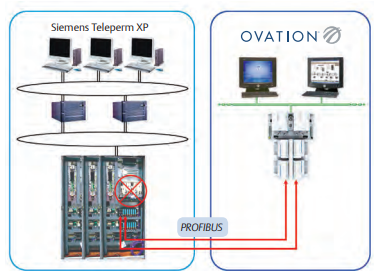

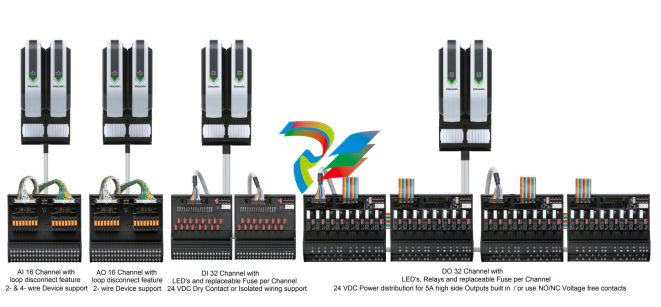

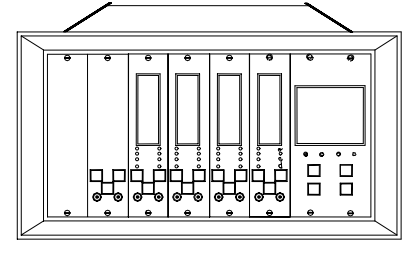

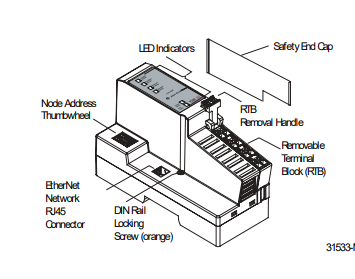

At its core, the Honeywell 8C-PCNT02 features a high-density I/O configuration capable of handling complex control tasks with ease. It supports multiple analog and digital inputs and outputs, providing seamless integration with a variety of sensors, actuators, and control devices. This flexibility ensures that the 8C-PCNT02 can be customized to suit specific system requirements, whether monitoring critical process variables or driving intricate control loops. The unit’s solid-state construction and industrial-grade components guarantee outstanding durability, allowing it to operate reliably under harsh environmental conditions typical of power plants and petrochemical facilities. Additionally, its fast response time and high accuracy contribute to improved process stability and operational efficiency.

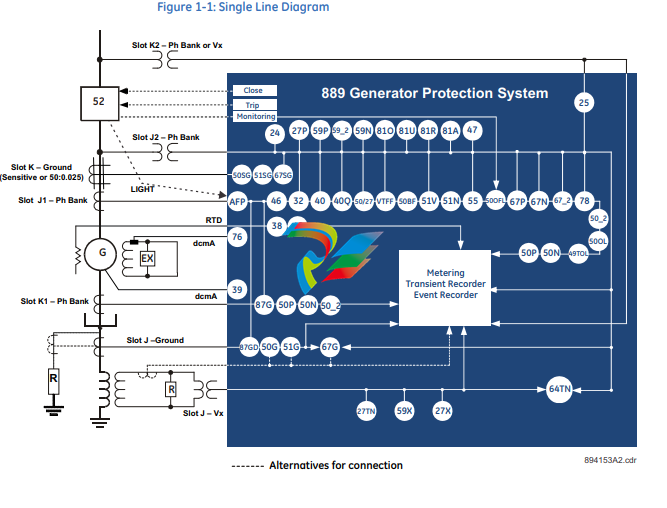

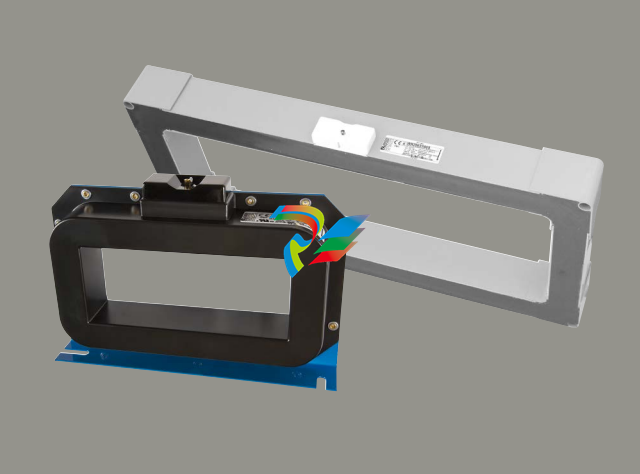

In real-world scenarios, the Honeywell 8C-PCNT02 excels in environments where precision and reliability are non-negotiable. For example, in the power industry, it can be deployed to monitor turbine parameters, regulate voltage and current inputs, or manage safety interlocks. Its rugged design ensures uninterrupted performance despite exposure to temperature extremes, vibration, and electrical noise. Similarly, in petrochemical plants, the 8C-PCNT02 helps optimize chemical process controls, ensuring consistent product quality and safe operation through precise measurement and control of pressure, flow, and temperature. General automation tasks such as factory floor monitoring, machine control, and system diagnostics also benefit from its adaptable input/output capabilities and robust communication protocols, making it a versatile solution across various sectors.

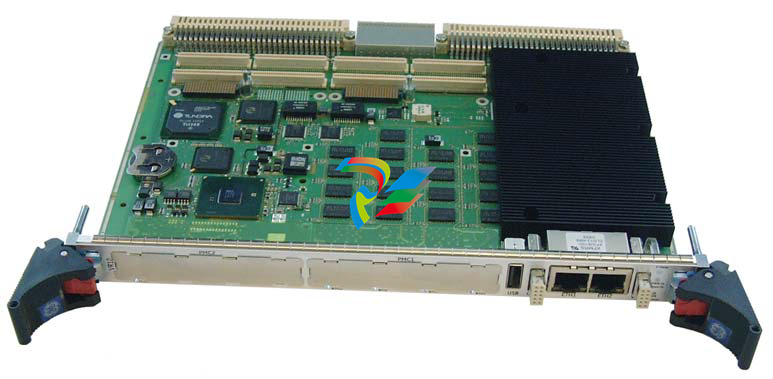

When compared to other Honeywell automation products, the 8C-PCNT02 offers unique advantages. Unlike the Honeywell 1736/EUS, which is primarily designed for distributed control system (DCS) interfaces, the 8C-PCNT02 delivers a more compact form factor with enhanced I/O density and faster processing speeds. Compared to the Honeywell SP711, known for its specialized sensor capabilities, the 8C-PCNT02 provides broader compatibility with diverse sensor types and control signals. Moreover, while the Honeywell VM1A excels in basic monitoring functions, the 8C-PCNT02 extends functionality with advanced diagnostics and real-time data processing, enhancing system intelligence. Its ruggedness surpasses models like the Honeywell RCZ851K, which, although reliable, is better suited for less demanding industrial environments.

Alongside the Honeywell 8C-PCNT02, complementary Honeywell automation products such as the Honeywell PC400 and Honeywell PC700 provide scalable control and visualization options, enabling comprehensive system integration. The Honeywell FC-SCNT02 offers specialized sensor interfacing, enhancing the data acquisition capabilities when paired with the 8C-PCNT02. For communication and safety functions, models like the Honeywell DR45AR-1111-40-002-0-500000-0 and Honeywell CC-PAIX02 serve as ideal partners, ensuring secure and efficient data transmission. Additionally, Honeywell’s Honeywell 51401577-100 and Honeywell 620-1690 modules expand the input/output configurations available, allowing system architects to tailor solutions precisely to operational needs.

The application of 8C-PCNT02 in power industry, petrochemical, and general automation is further supported by Honeywell’s extensive ecosystem of products, including the Honeywell 1153304-2 and Honeywell 51304903-100, which complement the 8C-PCNT02’s monitoring and control capabilities. This interconnected portfolio ensures that whether upgrading an existing system or designing a new automation solution, users benefit from seamless compatibility and enhanced performance.

In summary, the Honeywell 8C-PCNT02 is a powerful, durable, and versatile automation product that excels in demanding industrial environments. Its advanced input/output capacity, combined with rugged construction and superior performance metrics, make it ideally suited for critical applications in the power industry, petrochemical plants, and general automation. When deployed alongside other Honeywell automation products such as the Honeywell 1736/EUS, Honeywell SP711, Honeywell PC400, and Honeywell DR45AR-1111-40-002-0-500000-0, it forms a comprehensive, reliable solution that drives operational efficiency and safety. For professionals seeking dependable and scalable automation solutions, the Honeywell 8C-PCNT02 represents a smart investment backed by Honeywell’s proven technological expertise.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|